Dunce Bot: The Soldering Do-Boy I Didn’t Mean to Build

- Rich Washburn

- Dec 30, 2025

- 3 min read

OK, so here’s the deal:

Among the stuff I got for Christmas this year was one of those servo-motor kits. Five servos. A handful of DC motors. A couple of H-bridges. Basically, a little box of “make things move” for adults who still void warranties for fun.

Naturally, I cracked it open Christmas night — because what else are you going to do when you’ve got free time and freshly printed datasheets?

I’d never really messed with servos before. I live mostly in the world of AI, infrastructure, and digital architecture — abstract stuff. But this? This was IRL. Real motion. Real feedback. Real smoke potential.

So I dove in.

“Cool, it moves. …Now what?”

A few hours later, I had an ESP32 driving everything beautifully.Sliders on a web page. Servos twitching on command. REST endpoints because of course.

And then I hit the existential moment every maker knows:I could make things move.I just had no idea what to move.

Then I looked over at my soldering setup — that old metal base with the two alligator clips I’ve been using for years.The one that never quite holds the board right. The one I constantly have to flip, rotate, and fight just to solder the other side.

And I thought: “What if I had a little robot that did that for me?” Cue the montage.

By the end of the night, I was standing in my own Tony Stark-style garage, surrounded by wires, blinking LEDs, and the faint smell of victory and flux.

The Build (Creative Inertia + Mild Insanity)

This thing came together like building a car at 60 mph while realizing halfway through that you’re also designing the road.

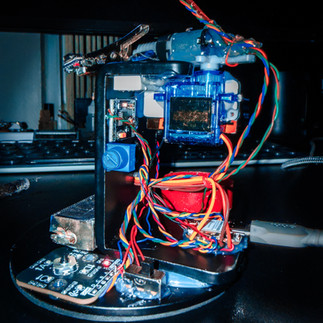

By 3 a.m., I had Dunce Bot — a compact, USB-C-powered, Wi-Fi-enabled, voice-controlled soldering assistant that looks like it crawled off the cutting-room floor of Iron Man 1.

Specs-ish:

Brain: ESP32 DevKitC

Motion: 2 × SG90 servos + 1 × low-geared DC motor (H-bridge driven)

Lighting: Single Neopixel halo spotlight

Cooling: 30 mm brushless fan for smoke extraction

Hardware: Magnetic heatsink block + metal solder-sponge cup with magnet base

Interface: 5-way tactile joystick, local web controls, REST API, and Siri Shortcuts because why not

It’s ridiculous. It’s unnecessary. It’s beautiful.

Why “Dunce Bot”?

Because around 2 a.m., I made it a paper hat that said DUNCE and taped it to the top.

It just fit.

This thing’s brilliant enough to obey network commands and dumb enough to melt itself if I’m not watching. It’s the perfect lab partner: loyal, impulsive, a little dangerous, and always game for chaos.

It’s not a helper. It’s a do-boy. It does what it’s told — mostly — with the same earnest energy as Stark’s DUM-E, minus the corporate budget.

It Actually Works

And that’s the scary part.

I can literally say, “Hey Siri, rotate Dunce Bot fifteen degrees left,” and it does it. It re-aims the board, fires up the fan, flips the light.

It’s like a tiny workshop intern that never sleeps and doesn’t complain about the smell of rosin.

Next Version: Dunce Bot 2.0

Yeah, of course I’m already planning the sequel.

The side-to-side servo skips a bit, so I’ll swap in a smoother motor. The rotation drive’s perfect. And after that?

I’m thinking vision. An ESP32-CAM module so it can see the work area and preempt my movements. Imagine it tracking my hand, anticipating when I pick up the iron, and adjusting automatically. That’s either genius… or the opening scene of Iron Man 4: Florida Man Edition.

A Quick Thought...

It’s wild how short the distance has become between “what if” and “holy crap, it works.”

This wasn’t a plan. It was curiosity with a soldering iron. Now it’s a voice-controlled, network-aware desk creature with a paper hat and a purpose.

So yeah — that’s Dunce Bot. Born from boredom, forged in flux, and living its best life on my workbench.

Stay curious. Stay ridiculous. And if you’re gonna over-engineer something, at least give it a hat.

#DunceBot #MakersGonnaMake #DIYElectronics #ESP32 #Microcontrollers #ServoControl #IoTProjects #RestAPI #HomeLab #HackTheDesk